DCVC leads Reach Labs’ $9M Series A to make scalable, far-field wireless power a reality

Nikola Tesla dismissed the idea of using radio waves to transfer electricity 130 years ago. Despite evidence to the contrary, he insisted that radio waves could only move in a straight line, and that they faded too quickly to transmit power (or information).

Instead, Tesla thought that he could harness and amplify the Earth’s own electrical charge by shocking it at the right frequency. He saw some experimental success, once powering 200 lamps 25 miles from his laboratory, but only accomplished this by pumping 100 million volts of electricity into the ground. Tesla built a 200-foot tower to advance this dangerous method, but after a series of complications – funding problems, a competitor’s success, and the murder of the tower’s architect – he lost the tower to foreclosure. Wireless power research stagnated, and Tesla stubbornly mocked and mischaracterized radio waves for decades to come.

Today, Reach Labs is harnessing the same radio waves Tesla belittled to make long-range wireless power a reality. The company has built a hardware platform that uses unique power path generation and routing algorithms to maximize power transmission and minimize risk. Reach Labs has customers interested in everything from wirelessly powering drone swarms to making a construction site’s cordless power tools truly cordless.

DCVC invested in Reach Labs because of:

- Their adaptive hardware and multi-path algorithms that make long-range wireless power inexpensive, compact, viable, efficient and safe by every regulatory standard;

- Their hardware architecture that scales inexpensively, reliably, and predictably: from the milliwatts of medical devices and wearables, to the multiple watts of mobile devices, to the kilowatts of electric motors;

- The performance and lifetime improvements their technology brings to all electronics, transforming existing markets;

- The doors wireless power opens for the invention of new devices, and new markets by extension.

The company’s exciting applications notwithstanding, we’re going to focus on a humble (but frequently critical) application for Reach Labs: wireless sensor networks – distributed collections of sensors used for everything from environmental monitoring to tracking terrorists.

In the short term, Reach Labs will impact every industry using wireless sensors because the problem they solve is universal: sensors are battery-powered, and batteries are short-lived and inconvenient to replace (as noted below, sometimes tens of millions of dollars of inconvenience). In the long term, wireless power will change society as much as wireless information has.

Wireless Power and Critical Sensor Networks: A Perfect Pair Waiting for the Right … Spark

Reach Labs is first bringing wireless power to wireless sensor networks (and other industry applications) because of the power limitations inherent in those systems. Wired power isn’t an option for many sensor networks because they operate in inaccessible areas – the interior of a nuclear reactor, for instance, or the inside of heavy manufacturing equipment.

Shutting down these machines and taking them apart to replace dead sensor batteries can take significant time and cost millions of dollars. Alternately, the sensors might be too mobile for wired power – like animal trackers or medicine vial monitors – or they could be too numerous to wire inexpensively. Sensors also have to balance complex energy trade-offs concerning network architecture, sleep/wake cycles, and data processing and transmission. Some nodes are used more than others, which means (under battery power) they die faster. Replacing these batteries quickly becomes an expensive, time-consuming ongoing process, but without it, the wireless sensor network dies.

The net (pun intended) is that without practical wireless power, unhappy compromises exist for every sensor network in terms of desired frequency of update, resolution of data, bandwidth, range, and local compute capability. And, shutting huge complex systems downs to replace batteries, even if just once a decade, can cost many millions to tens of millions of dollars.

Network lifetime – how long engineers can stave off a network’s inevitable demise – is something network designers have been trying to maximize since the earliest wireless sensor systems. In the early 1950s, the US Navy deployed a network of underwater acoustic sensors for detecting Soviet submarines: the Sound Surveillance System (SOSUS). While not technically wireless – the sensors were tethered to land bases by miles of undersea cable – SOSUS is considered the earliest modern example of a sensor network. A few of its bases are still operating today, but instead of tracking submarines, they’re studying underwater earthquakes, measuring ocean temperature, and recording whale songs. Only a few of the SOSUS nodes are still operating today, but its designers would be pleased to see them running after more than 60 years.

The invention of wireless communication spurred the adoption of wireless power sources, and by extension shorter power supply lifetimes. DARPA spearheaded the first big push for wireless sensors as they explored uses for ARPAnet in sensor network communications. They established the Distributed Sensor Networks program in 1980, and associate researchers from MIT and CMU worked on developing the infrastructure needed to make sensor networks wireless. CMU researchers created an operating system that facilitated access to distributed resources, and MIT researchers built a proof-of-concept sensor network that could track aircraft with acoustic and video sensors.

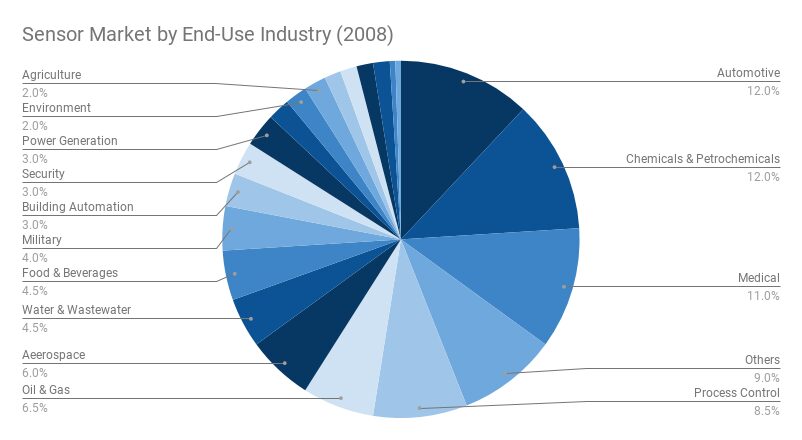

As with most DARPA research, distributed sensor networks were first applied to military problems like target tracking and battlefield monitoring, but as sensor size and cost fell, they gained traction in research, industrial, and consumer settings. Small, cheap sensors emerged for a variety of new applications across industries – and they continue to do so today. The wireless sensor network market generated $29.06 billion in revenue in 2016 – a number expected to grow to $93.86 billion in 2023.

As wireless networks have gained popularity, network lifetime has improved (thanks to battery advances), but emerging network applications have lifetime requirements of years – sometimes decades – that current batteries are unable to support. Some sensor networks meet these requirements by harvesting energy from their surroundings. Industrial machinery sensors can convert the machine’s vibrations into energy. Outdoor networks can run on solar power if the environment is suitable. Some water-monitoring networks can even harness flowing water to power their sensors. Energy harvesting requires very specific environmental conditions, though, and most sensor network sites don’t meet those conditions. Even in the right conditions, many energy harvesting mechanisms don’t deliver enough power to run the network, and they require upkeep that makes them expensive in the long run.

Wireless sensor networks’ energy and energy harvesting limitations make wireless power transfer a promising alternative. But wireless power hasn’t really worked reliably, inexpensively, or safely much past a meter or so – until now.

Wireless power comes in two flavors: near-field and far-field. If you’ve been to a Starbucks in the last 3 years, you may have seen near-field charging pads embedded in the tables. These pads charge devices inductively – they use a wire coil to make an electromagnetic field that transfers energy to devices placed on top of it. This type of wireless charging has been one of the most commercially successful so far, but it only has a range of a few centimeters.

Far-field wireless charging isn’t limited in range the same way near-field methods are, but some approaches are dangerous if used improperly. Imagine Tesla pumping 100 million volts of electricity into the ground close to a pond. Thankfully, far-field wireless power has evolved since Tesla’s experiments. Harrell Nobel showcased the first successful wireless power transfer using radio waves at the 1933 Chicago World’s Fair, and researchers have been experimenting with wireless power for aircraft and satellites since the late 1960s.

Far-field wireless power can be light-based or microwave-based. Light-based power transfer methods – lasers and visible light – are expensive, difficult to scale, and can only transfer energy to devices in their line of sight, which makes them unsuitable for most applications. Radio wave- and microwave-based methods aren’t limited by line of sight, but their radiative waves must be shaped into dense beams to carry any useful amount of energy over a distance. Those beams must be low-energy per cubic cm of intersecting human tissue, though, since too much exposure to radio waves can harm living things. You wouldn’t want to be caught in a stray high-energy microwave beam, for instance.

This is where Reach Labs comes in. They use radio waves to transfer power wirelessly (and safely) by sending it through multiple pathways instead of in a single, concentrated beam. Their hardware enables non-line of sight power transfer that is safer, more efficient, longer-range and more powerful than anything else on the market – and it operates at chip-scale, without exotic materials or processes.

Sparking Change: How Reach Labs Transforms Wireless Power

Wireless sensor networks are only one of the company’s first applications, but it’s a great example of how transformative Reach Labs’ technology is to the industries it touches. Removing the single largest design limitation for the Internet of Things will have widespread impacts: power-hungry video and audio sensors will become more viable; networks in volatile locations will remain operational despite lost nodes; sensors in security applications will no longer be vulnerable to power loss. Network lifetime is the single variable every wireless sensor network aims to maximize, and Reach Labs is providing a way to extend it indefinitely.

Truly wireless sensor networks are only the first step in changing the way we power electronics. Imagine an autonomous warehouse where the robots don’t need to charge themselves – there would be no need for extra machines to replace their paralyzed peers – or a swarm of security drones that never need to land. Cordless power tools might become so cordless that they spend their lives hundreds of miles from a power outlet. Ubiquitous wireless power would shape the world in exciting, unpredictable ways.

Reach Labs is a turning point for wireless power because their unique hardware design finally makes this technology viable at scale. Their system is made of a power transmitter (Station) and power receivers (Targets) that map their surroundings and use optimization algorithms to direct power transfer. The Station keeps track of the battery status of all the Targets on the network. When a Target is running low on battery, the Station sends out low-intensity radio waves on multiple pathways, searching for the best path combination to charge the Target. These radio waves bounce off of obstacles, so they can reach the Target even if it is outside the Station’s line of sight. If the Target moves or an obstacle disrupts a path, the Station senses the decreased charging efficiency and recalibrates the paths to account for the change. Once the Station finds the optimal path combination to the Target, it strengthens the radio wave signal to charge the Target. Each Station can reach Targets up to 60 feet away, and the system can run anything from microwatt sensors to 400 watt industrial robots. This dynamic, multi-pathway approach takes wireless power variables historically at-odds with one another – size, safety, range, power, efficiency – and makes them complement each other instead.

You’re probably reading this article on a device that hasn’t had a wired internet connection for the better part of a decade – if at all. In another ten years, your charging cables might be equally outdated.

We invested in Reach Labs because we believe they will do for electricity what WiFi has done for information. Their novel hardware brings us closer to ubiquitous wireless power than we have ever been before. We’re excited about the deep technological breakthroughs Reach Labs has made so far, and we look forward to seeing them deploy their hardware in the industrial sector soon.

Ready for the next step?

Let’s Power Your Future Together!