Whenever I mention wireless power to someone, the first thing they say is, “I have that on my desk; it’s a little pad I set my phone on.” And yes, that is wireless power. In particular, it is a type of wireless power known as induction, which is similar to what your electric toothbrush uses. But Reach does something quite different, and, honestly, almost magical. We send wireless power “at-a-distance,” which means the device doesn’t have to be next to the charging station; it can be tens of feet away – and we do this not just in the home but in industrial environments and with industrial scale.

A good way to think about our solution is that it transforms power the way Wi-Fi transformed data. What does that mean? Until 1999, the year IEEE 802.11b was rebranded “Wi-Fi,” computer networking was largely a matter of stringing cables between servers, computers and other peripheral devices. Over the following two decades, W-iFi became the dominant way to connect most devices throughout the home and enterprise.

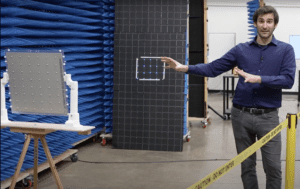

Reach does much the same, but for power. Reach uses a sophisticated adaptive antenna array transmitter, which we call a ‘router,’ to safely send highly directed beams of power to devices throughout your environment. To power a broad range of devices in an industrial setting, a solution must meet a number of requirements. Some are table stakes, achievable with any successful first-generation wireless power solution. Others really take you to the next level – what we call next-gen or industrial-scale wireless power. Let’s look at both sets of requirements.

Wireless Power Basics

There are three basic requirements any wireless power solution needs to meet – safety, ease-of-use, and reliability. Safety comes first. In the United States, all wireless power solutions must operate within the radio frequency (RF) exposure limits set by the Federal Communications Commission (FCC). Reach complies with those parameters via our redundant safety protocol. Two independent systems are constantly monitoring the broadcasted energy to ensure that no living creature can enter or be impacted by the power beam.

The next basic requirement is ease-of-use. The Reach solution is easy to install, easy to manage, and requires no extensive training or dedicated personnel. If you can point and click, you can run your power network. Power reliability is the last basic requirement; a wireless power system must work all the time. The Reach system is designed for mission-critical scenarios, including military and defense settings, and it meets that standard.

The Four Attributes of Industrial-Scale Wireless Power

On top of those three basic capabilities that get you a seat at the wireless power table are another four attributes that distinguish a solution as industrial-scale:

- “Wi-Fi” Range. An industrial-scale solution needs distance. Reach’s solution works at similar ranges to your Wi-Fi network. In practice and as with Wi-Fi, the effective distance will vary based on the infrastructure, but it roughly translates into tens of meters. Wireless power can be effective at much greater – grid level – distances as well, and Reach is expanding on our prior projects with the U.S. Government to demonstrate this capability In practice..

- Lots of Power. It’s not just low wattage Internet of Things (IoT) devices that need power. An industrial-scale solution can power a broad range of devices found in an enterprise or, naturally, an industrial environment, including high-wattage cameras, tools, small robots, and sensors. Most other companies’ solutions are focused on devices that use less than one watt of power, thus failing to meet broader demands. Reach can power devices covering a wide range of power requirements from milliwatts to tens of watts – more than ten times greater than the status quo.

- Support for a Multitude of Devices. Like Wi-Fi, an industrial-scale wireless power network needs to be point-to-multipoint (P2MP). By contrast, a point-to-point (P2P) powering configuration is little more than an extension cord, inadequate given a large number of endpoints on a manufacturing floor or other enterprise setting. Exploiting non-line-of-sight capabilities, the Reach P2MP transmitter detects, authorizes, and powers all user-approved devices within a given environment.

- Intelligent. An industrial-scale solution must be smart, efficiently maximizing power to multiple devices, collecting and analyzing relevant operational data, and offering value-added information to end users who need insights on device failures or those that are using too much power. Reach’s algorithms optimize power to each device and our management system reports operational data, which enables optimized deployments.

Hardened, Like Wi-Fi

At its inception, Wi-Fi was a consumer-based technology, providing an alternative to wired home-networking schemes. But over time, engineers upgraded and hardened Wi-Fi to satisfy the more stringent requirements of enterprise and industrial customers. Wireless power is moving beyond its early iterations. Leveraging lessons-learned and aspiring to move the industry forward, we designed the Reach system from the start with more powerful, industrial-scale attributes.

If you are seeking the full benefits of wireless power-at-a-distance, you’ll of course want a solution that is safe, easy-to-use, and reliable. But more than that, you’ll need one that delivers the distance, wattage, P2MP capability, and intelligence that allows you to make the most use of this amazingly transformative technology.